Sustainable

Solutions

Resource Efficiency & CircularityDecarbonizationDigitalization & Innovation

Sustainable Solutions

Sustainability is integral to our business strategy. We are committed to implementing sustainable practices across our operations and developing innovative solutions that enable our customers to achieve greater efficiency and productivity.

Advancing Bystronic’s cleantech solutions

Through its commitment to sustainability-led innovation, the company focuses on material and energy efficiency across our customer offerings. Bystronic conducts life cycle analyses (LCAs) and eco-design principles in developing its products. Bystronic’s cleantech solutions portfolio encompasses a range of systems, services, and software that increase material and energy efficiency. These include products such as laser sources and chiller systems that reduce energy, and metal bending and cutting technologies that reduce waste.

Energy efficiency

30%

(save up to 30%)

- Energy efficient laser

- Energy efficient chiller

- Deep Standby

- Waste heat management

- Nitrogen generator

Circularity

20%

(20% recycled material)

- Modular design

- Long life consumables

- >20% recycled materials

- Refurbishment

Material efficiency

15%

(save up to 15%)

- Residual sheet management

- Advanced Nesting

- Parameter Wizard

- Intelligent Cutting Process (ICP)

- NCT & KerfScan

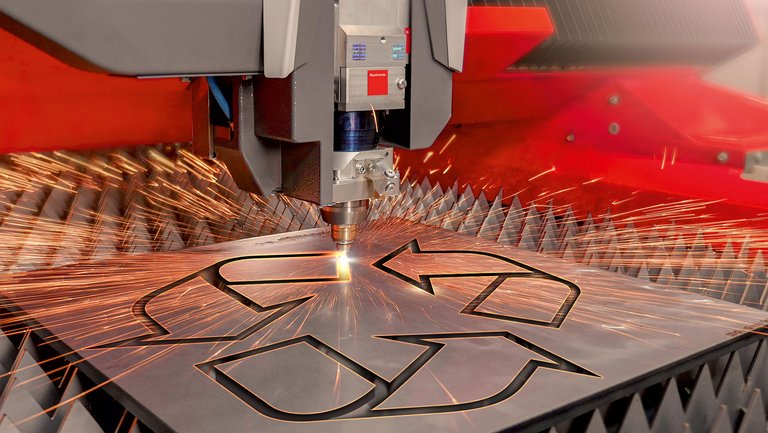

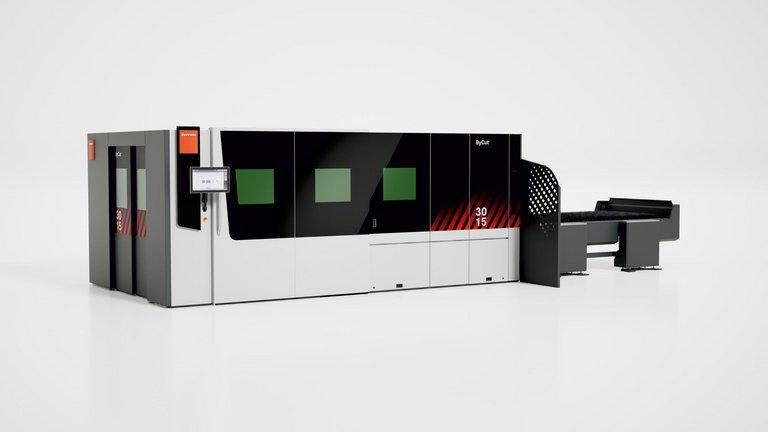

Sheet metal cutting systems

Bystronic’s commitment to improving operational efficiency and sustainability is visible through the resource and energy efficiency features integrated into our fiber laser cutting and bending machines, which are designed to optimize material use, reduce waste, and increase productivity.

Advanced Nesting: A software feature that optimizes fiber laser cutting can save up to 14% metal consumption for the same production volume. With dedicated user training, the software optimizes the cutting plan by narrowing web widths, increasing the number of parts on the cutting plan, and adjusting the cutting path to minimize waste. Additionally, it adjusts laser power and speed based on the material and sheet thickness. By analyzing the size and shape of residual sheets, the software identifies the most efficient way to use them in subsequent cutting processes.

Intelligent Cutting Process (ICP): ICP uses a coaxial camera to film through the nozzle, monitoring the cutting process and ensuring reliability through proactive and reactive actions. This reduces downtime and material waste in case of nozzle loss. By preventing unrecognized cut interruptions, the ICP feature helps minimize waste.

Parameter Wizard with Artificial Intelligence (AI): This feature combines intelligent human-machine interaction and AI-based optimization to support the operator when a new type of metal is introduced to optimize cutting quality. Leveraging AI swiftly and accurately helps obtain the correct parameters, eliminating the need for time-consuming trial and error methods.

Nozzle Control Tool (NCT) & KerfScan: NCT enables automatic nozzle centering in seconds, and nozzle condition and type monitoring. KerfScan examines the oxygen cut to detect residual slag inside the kerf, allowing for recutting parts as needed. This combination ensures a consistent, high-quality cutting process that reduces waste and rejected parts.

Laser source and chiller systems: Laser sources and chiller systems are the core of our laser cutting machines and the main drivers of energy consumption and carbon emissions. As part of our commitment to deliver cleantech solutions, we have identified significant R&D potential in optimizing the energy performance of our laser sources and chiller systems.

Energy efficiency

60%

(save up to 60%)

- Servo Hydraulic

- Energy Saver

- Deep Sleep Mode

Circularity

20%

(20% recycled material)

- Modular design

- Long durability

Material efficiency

5%

(save up to 5%)

- Dynamic Crowning

- Laser Angle Measurement System

- Intelligent Sheet Follower

- Material optimized offline software BySoft CAM

Sheet metal bending systems

Servo hydraulic & energy saver: Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction. Energy Saver SERVO has 62% less energy consumption compared with conventional hydraulic bending machine.

Modular design: Modularity is used to build bending machines ensuring common parts are used, simplifying repair and spare part logistics, enhancing efficiency, and extending product lifespan. Moreover, the modular nature of Bystronic’s machines allows for tailored configurations to meet specific customer requirements.

Laser Angle Measurement System (LAMS): LAMS ensures precision and productivity by eliminating the need for time-intensive measuring and correcting parts. It optimizes metal waste reduction by achieving precise angles and minimizing misshaping, ensuring that even the first bend is flawless.

Decarbonization

Since the beginning of our sustainability journey, Bystronic has improved the energy efficiency of its manufacturing processes, increased the electrification of fleet vehicles, and sourced renewable energy to heat buildings, plants, and sites worldwide.

Managing Climate-Related Risks and Opportunities

Climate-related risks and opportunities are included within Bystronic’s overall risk management framework. This process involves identifying and assessing risks at the Group level. It is conducted through interviews with experts and leaders and is overseen by the Internal Audit and Legal Departments every year. In 2024, this process included approximately 20 members from the Group’s Executive Committee and Board of Directors. Equally important is the biennial materiality assessment, a crucial part of our risk management, which informs and involves stakeholders in identifying and prioritizing material ESG issues.

Suppliers Scope 3 upstream

24%

Purchased goods & services: 245 kt CO2e

Operations Scope 1 and 2

1%

Operations & services: 10 kt CO2e

Customers Scope 3 downstream

75%

Use of sold products & services: 771 kt CO2e

Scope 1 and 2

CO2e emissions in 2024

Tons of CO2e and in %

Scope 3

CO2e emissions in 2024

Tons of CO2e and in %

Resource Efficiency & Circular Economy

Bystronic’s vision of the circular economy combines circular approaches, such as recycling, reuse, and extended lifespan, with a business model transformation from machine manufacturer to full solutions provider. To sustain this vision, we set a 2030 target to reduce waste by 20%.

2030 sustainability targets

20%

Waste reduction (over 2021 baseline)

Circulus project

In the Circulus project, Bystronic is conducting with Innosuisse a detailed evaluation of the opportunities and potential of the circular economy in sheet metal processing and mechanical engineering in general. The focus is on extending product life cycles, sustainable business models, and resource efficiency. The insights gained will be implemented in the company’s global production sites, service and maintenance offers and in the sustainable design of the products and solutions sold.

Digitalization & Innovation

Our customers in the sheet metal industry are shifting their focus from capacity to productivity. Digitalization is key to this transformation and offers significant advantages.